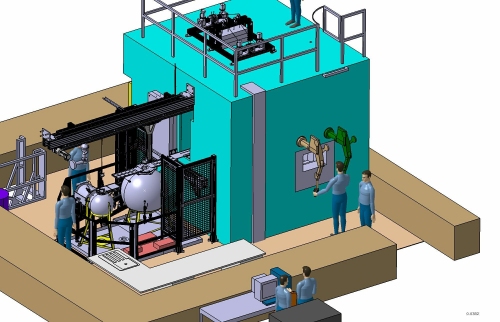

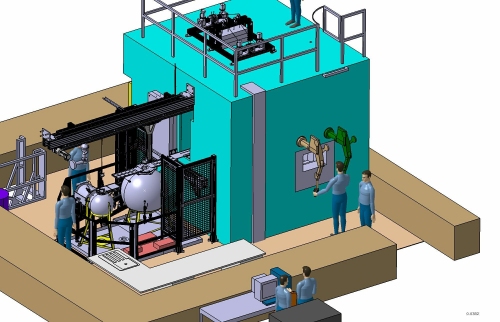

4 axis control system and mechanical components for NPL Manganese Bath

A turnkey solution package was required to replace an existing but unreliable system

Application or solution

A turnkey solution package was required to replace an existing but unreliable system for the new laboratory building installation. Incuding: Initial Sizing and specification,Mechanical units ( Linear Actuators, Motors, Gearheads, Absolute Encoders), Electrical control ( multi axis), Visual Basic Software Screen Package, Installation, Commissioning and Training.

Scope of overall contract.

Design, Justify, Innovate, Build, Program, Test, Demonstrate, install, commission, train operators. Devise user manual.

Description of equipment and services supplied.

The Manganese Bath Laboratory at NPL is a facility for processing particular ‘active’ sources by extracting them from a ‘safe’ storage pit location, carrying them by linear motion remotely safely and accurately and depositing them into one of two special spherical chambers called manganese baths. Then after processing returning them safely to the storage pit. Although the ‘active’ enclosure area can be entered by operators clad in protective suits for necessary intervention it is not desirable and the main process work needs to be carried out by using remote control arms and programmed routines.

The main motion system comprised:

a) Heavy Duty X-Y Belt driven servo linear actuators with absolute encoding.

b) 4-axis stepper motor driven worm-gear winch units for source extraction form pit.

c) Large linear-actuator stepper / gear driven safety-door for source cell enclosure.

d) Dual points of control with HMI operator panels in the active area and outside.