Mon 9th May 2022 - Hydraulic systems can be complicated

Simplify your customers' machines designs with electric actuators

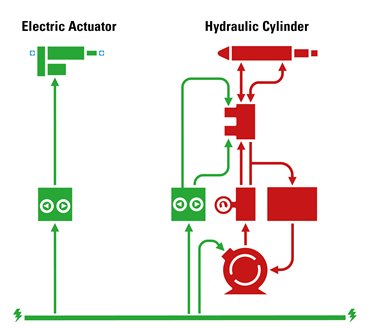

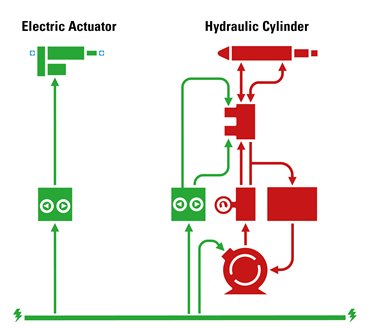

The process of utilizing hydraulics to create linear motion requires a complicated external system - even the smallest system needs eight separate moving components, which raises the risk of failure to above average. As oil pumps through the system, filters may clog; oil levels may drop; bearings, seals and gears may deteriorate - all of which can contribute to leakage, noise and other problems.

Other hydraulic system issues include:

- They consume valuable space, which makes it difficult to design for today's compact designs.

- Even when operating at peak performance, the large number of components creates distracting noise.

- Noise-mitigating products add more design challenges and costs.

- The requirement of idling systems consumes more energy, driving up operating costs.

- The common need for multiple hydraulic cylinders increases the complexity and related issues.

Thomson electric

actuators provide a simplified alternative to hydraulic systems

Electric

actuators have advanced to provide the high-load advantages of hydraulic systems but without the drawbacks. Instead of complex hoses, valves, pumps and other assemblies, electric linear actuators embed all of their functionality in the actuator housing itself, which connects an electronic control unit with only a few wires. The image above shows a comparison of the two options, revealing the simple operation of electric actuators.

Disclaimer

The use of this news article and images came with permission from Thomson.

Electric actuators have advanced to provide the high-load advantages of hydraulic systems but without the drawbacks. Instead of complex hoses, valves, pumps and other assemblies, electric linear actuators embed all of their functionality in the actuator housing itself, which connects an electronic control unit with only a few wires. The image above shows a comparison of the two options, revealing the simple operation of electric actuators.

Electric actuators have advanced to provide the high-load advantages of hydraulic systems but without the drawbacks. Instead of complex hoses, valves, pumps and other assemblies, electric linear actuators embed all of their functionality in the actuator housing itself, which connects an electronic control unit with only a few wires. The image above shows a comparison of the two options, revealing the simple operation of electric actuators.