Tue 16th Feb 2021 - Kollmorgen Experts discuss how to best select a servo motor

There are several considerations when selecting a servo motor for a specific application, such as the required speed, torque or force, motion profile, available physical envelope, and environmental factors. This means that the chosen motor solution must produce the load torque and speed requirements, fit in the available space, and perform as required under the subjected environmental conditions of the application.

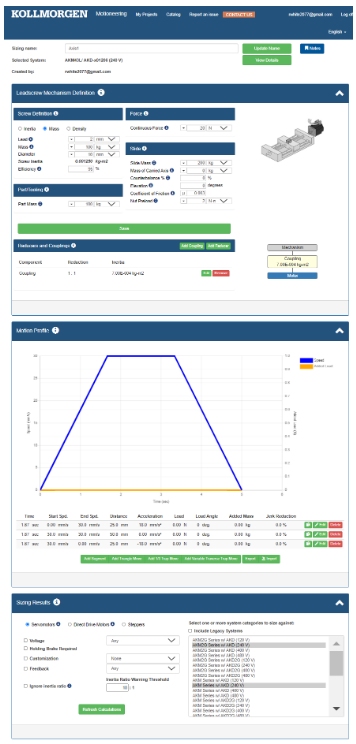

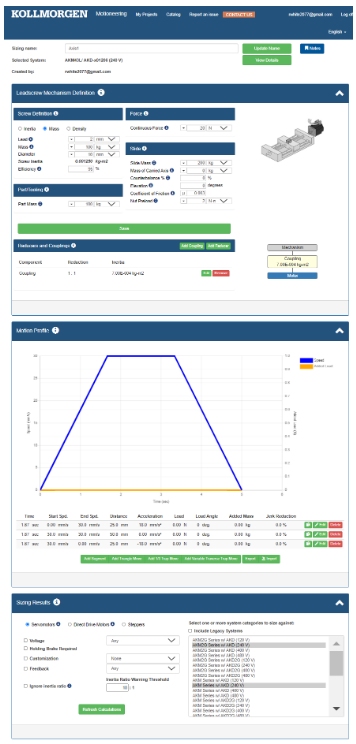

A servo motor is part of a total mechanism that provides motion to a load – to move it, machine it, lift it, inspect it, etc. The servo motor is the muscle that provides the necessary torque, force, and speed (required load point) to perform a given function. The fastest and most reliable way to determine these needs is with a

motor sizing tool that calculates the load points required by a motor and analyzes information about the load, transmission elements, and motion profile to select a motor from the motor database that matches the load parameters. As the initial load points are determined, the sizing tool checks for the optimum solution and narrows the motor choices based on the required torque, speed, inertial ratio, and associated margins acquired from the motor ratings.

A servo motor’s physical size is mostly determined by its continuous torque producing capability with a tradeoff between motor diameter and motor length. A longer motor with a small diameter can have the same torque rating as a shorter, larger diameter motor. Another way of achieving the power requirements is by using a smaller motor and multiplying torque through a gearhead or applying alternative technologies - such as a flatter, direct drive servo motor, a frameless or kit motor, or a linear motor. Each of these technologies has varying forms that can address specific space requirements.

Environmental considerations can affect the motor choice in several ways. In most applications, the motor’s operating ambient temperature remains below a motor’s rating (typically 40°C). The motors themselves generate a prescribed amount of heat (based on the continuous rating designated by the manufacturer) which is represented by a temperature rise of the windings and a maximum coil temperature. For example, if a motor that is rated to produce 10 lbft of torque in a 40°C ambient with a 130°C temperature rise and a maximum coil temperature of 170°C is placed in a 50°C ambient environment, the maximum coil temperature of 170°C will be exceeded when the motor is operated at the 10 lbft rating continuously. In this case, the motor’s continuous torque would be reduced unless a larger motor is selected. More exotic environments may require customized solutions, including alternate materials, special sealing arrangements, or other modifications. The motor performance can be adversely affected in extreme conditions, such as outer space, high altitude, and even submersible environments.

Know your application requirements but not the necessary torque and speed? Use Kollmorgen's

Motioneering tool to size your project and find motor and drive pairings that best fit your needs.

As a Gold Partner, Micromech are able to supply and provide expertise on

Kollmorgen products. Contact our sales team on

01376 333333 or

sales@micromech.co.uk for price and delivery or technical assistance.

Disclaimer

The use of this news article and images came with permission from Kollmorgen.

A servo motor is part of a total mechanism that provides motion to a load – to move it, machine it, lift it, inspect it, etc. The servo motor is the muscle that provides the necessary torque, force, and speed (required load point) to perform a given function. The fastest and most reliable way to determine these needs is with a motor sizing tool that calculates the load points required by a motor and analyzes information about the load, transmission elements, and motion profile to select a motor from the motor database that matches the load parameters. As the initial load points are determined, the sizing tool checks for the optimum solution and narrows the motor choices based on the required torque, speed, inertial ratio, and associated margins acquired from the motor ratings.

A servo motor is part of a total mechanism that provides motion to a load – to move it, machine it, lift it, inspect it, etc. The servo motor is the muscle that provides the necessary torque, force, and speed (required load point) to perform a given function. The fastest and most reliable way to determine these needs is with a motor sizing tool that calculates the load points required by a motor and analyzes information about the load, transmission elements, and motion profile to select a motor from the motor database that matches the load parameters. As the initial load points are determined, the sizing tool checks for the optimum solution and narrows the motor choices based on the required torque, speed, inertial ratio, and associated margins acquired from the motor ratings. Environmental considerations can affect the motor choice in several ways. In most applications, the motor’s operating ambient temperature remains below a motor’s rating (typically 40°C). The motors themselves generate a prescribed amount of heat (based on the continuous rating designated by the manufacturer) which is represented by a temperature rise of the windings and a maximum coil temperature. For example, if a motor that is rated to produce 10 lbft of torque in a 40°C ambient with a 130°C temperature rise and a maximum coil temperature of 170°C is placed in a 50°C ambient environment, the maximum coil temperature of 170°C will be exceeded when the motor is operated at the 10 lbft rating continuously. In this case, the motor’s continuous torque would be reduced unless a larger motor is selected. More exotic environments may require customized solutions, including alternate materials, special sealing arrangements, or other modifications. The motor performance can be adversely affected in extreme conditions, such as outer space, high altitude, and even submersible environments.

Environmental considerations can affect the motor choice in several ways. In most applications, the motor’s operating ambient temperature remains below a motor’s rating (typically 40°C). The motors themselves generate a prescribed amount of heat (based on the continuous rating designated by the manufacturer) which is represented by a temperature rise of the windings and a maximum coil temperature. For example, if a motor that is rated to produce 10 lbft of torque in a 40°C ambient with a 130°C temperature rise and a maximum coil temperature of 170°C is placed in a 50°C ambient environment, the maximum coil temperature of 170°C will be exceeded when the motor is operated at the 10 lbft rating continuously. In this case, the motor’s continuous torque would be reduced unless a larger motor is selected. More exotic environments may require customized solutions, including alternate materials, special sealing arrangements, or other modifications. The motor performance can be adversely affected in extreme conditions, such as outer space, high altitude, and even submersible environments.