Humotech was founded in 2015 on one simple question: Instead of building prototype after prototype, what if engineers could evaluate the design of prostheses, orthotics, exoskeletons and other wearable machine concepts by programming a robot to emulate them in real time while a user walked?

Challenge

The Humotech Caplex™ testbed platform is a modular system used throughout the U.S, Canada and Europe in single-axis and multi-axis applications that aim to optimize biomechanical motion in wearable robots for people of widely varying needs and body types. Given the broad scope of applications, high-performance, versatile motion is essential.

Caplex systems precisely activate multiple Bowden cables to stabllize motion across multiple degrees of freedom in response to unpredictable human movements. Actuation is controlled by up to five servo motors, and units can be daisy-chained together to accommodate all the axes any application may require. Forces are high, rapid bursts of velocity are required, and servo loops must respond within milliseconds. Only the highest-performing servo motors and drives would suffice.

The first Caplex systems used motors from a Kollmorgen competitor, but Humotech wanted to achieve higher performance, lower acoustic and electrical noise, and more responsive control.

Solution

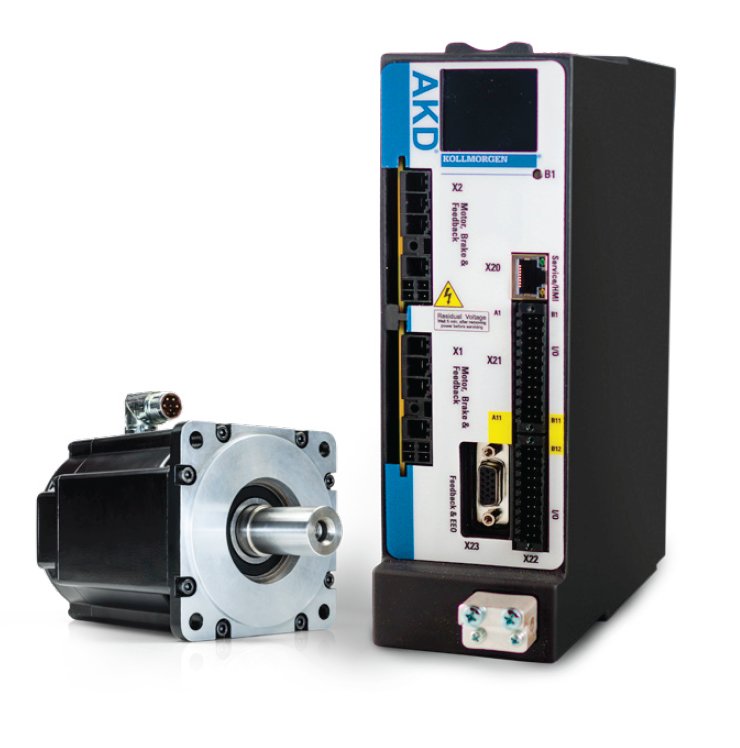

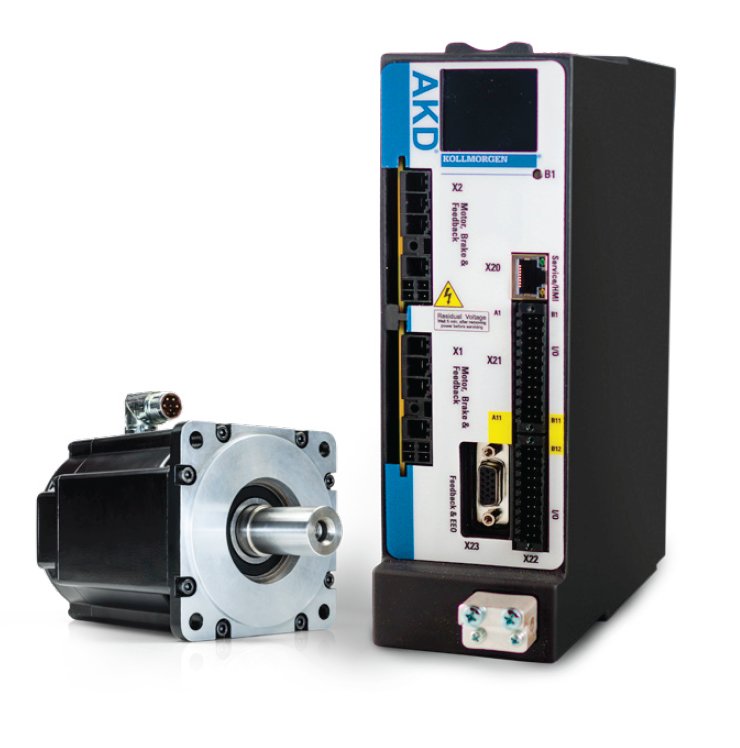

In collaboration with a Kollmorgen solution partner, Humotech selected AKD servo drives and AKM servo motors for integration into its wheeled, floor-standing Caplex units. A high-performance EtherCAT field bus is used for communication within Caplex systems and between daisychained units that provide as many as 10 or more axes of motion.

With the torque, speed and versatility of Kollmorgen servo motion, modular Caplex systems can easily be tailored to the needs of each project — including healthcare, rehabilitation, defense, consumer sports, wellness, healthy aging and other applications — with minimal custom engineering.

Results

ResultsThe servo performance is impressive, exceeding expectations. AKM servo motors deliver up to 2,420 rpm and 125 Nm torque, driving a maximum cable speed of 4.3 m/s and maximum cable force of 6.58 kN.

Kollmorgen AKD drives receive commands from an external controller hundreds or thousands of times per second based on a desired joint response, and the AKM motors respond with the appropriate speed and torque faster than the human nervous system can achieve. Actuators are quiet, efficient, easy to use, reliable and safe.

Caplex systems have been proven in more than 8 years of operation, and Humotech continues to refine and expand the system to serve more customers and applications.

Featured Products

AKM servo motors offer outstanding torque density and precision in the industry’s largest selection of standard servo motors and modifications for an ideal application fit.

AKD servo drives offer industry-leading performance, communication options and power levels in a compact footprint.

Disclaimer

The use of this news article and images came with permission from Kollmorgen.

Results

Results